Medical protective nonwoven fabric and regular nonwoven fabric differ in their composition and performance characteristics, primarily due to the specific requirements and intended applications in the medical field. Here are the key differences:

Composition:

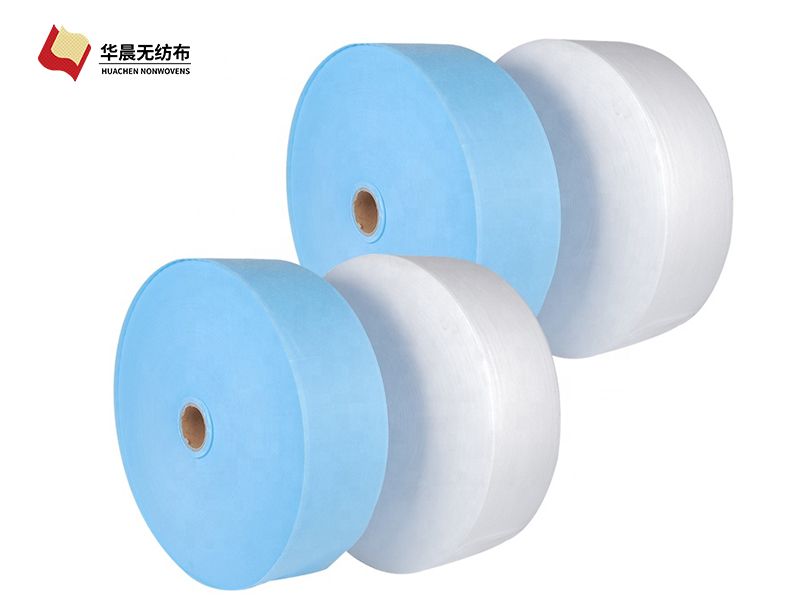

Raw Materials: Medical protective nonwoven fabric is typically produced using specialized fibers, such as synthetic polymers like polypropylene, polyethylene, or polyester. These fibers are chosen for their high strength, durability, and ability to repel fluids and microorganisms. Regular nonwoven fabric may use a wider range of fibers, including natural fibers like cotton or cellulose.

Additives: Medical protective nonwoven fabric often incorporates additives to enhance its performance, such as antimicrobial agents or hydrophobic coatings. These additives help in preventing the growth of bacteria and provide barrier properties against fluids. Regular nonwoven fabric may not have these specialized additives.

Performance:

Barrier Properties: Medical protective nonwoven fabric is designed to provide a high level of barrier protection against microorganisms, liquids, and particulate matter. It undergoes additional processing steps to enhance its barrier properties, such as lamination or the use of electrostatic charges. Regular nonwoven fabric may not have the same level of barrier performance.

Filtration Efficiency: Medical protective nonwoven fabric is engineered to have superior filtration properties, particularly in terms of particle filtration efficiency. It can effectively filter out microorganisms and particles of varying sizes. Regular nonwoven fabric may have lower filtration efficiency.

Fluid Resistance: Medical protective nonwoven fabric is treated to repel fluids, such as blood, bodily fluids, or water, to prevent them from penetrating through the fabric. Regular nonwoven fabric may absorb fluids or have lower resistance to liquid penetration.

Breathability: Medical protective nonwoven fabric strikes a balance between barrier properties and breathability to ensure comfort for the wearer. It allows air and moisture vapor transmission, reducing the risk of heat build-up and improving breathability. Regular nonwoven fabric may have different levels of breathability depending on its intended use.

Sterilization Compatibility: Medical protective nonwoven fabric is designed to withstand common sterilization methods like gamma irradiation, ethylene oxide (ETO) gas sterilization, or steam autoclaving without compromising its integrity. Regular nonwoven fabric may not be subjected to the same sterilization processes.