Nonwoven fabrics have become an essential material in various industries, from healthcare to agriculture, construction, and everyday consumer products. Among the wide range of nonwoven fabrics available, SMS Nonwoven Fabric and Spunbond Nonwoven Fabric are two of the most commonly used types. While they may appear similar at first glance, they possess distinct characteristics, manufacturing methods, and applications. Understanding these differences is key for manufacturers, designers, and consumers seeking the most suitable fabric for their needs.

Understanding Nonwoven Fabrics

Before diving into the specifics, it is helpful to briefly define what nonwoven fabrics are. Unlike traditional woven or knitted fabrics, nonwoven fabrics are made by bonding or interlocking fibers mechanically, thermally, or chemically. This process creates a fabric that does not require weaving or knitting, offering flexibility in thickness, strength, and texture. Nonwoven fabrics are generally lightweight, cost-effective, and can be engineered to meet specific performance requirements, such as filtration, liquid repellency, or softness.

Two widely used nonwoven fabrics are SMS Nonwoven Fabric and Spunbond Nonwoven Fabric. Both are polymer-based and share certain characteristics, but their differences are crucial in determining their functionality.

What is Spunbond Nonwoven Fabric?

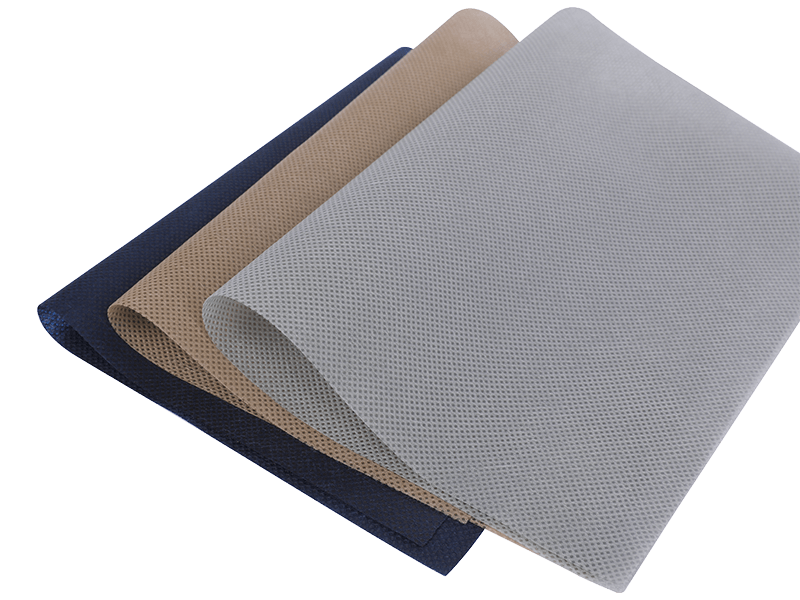

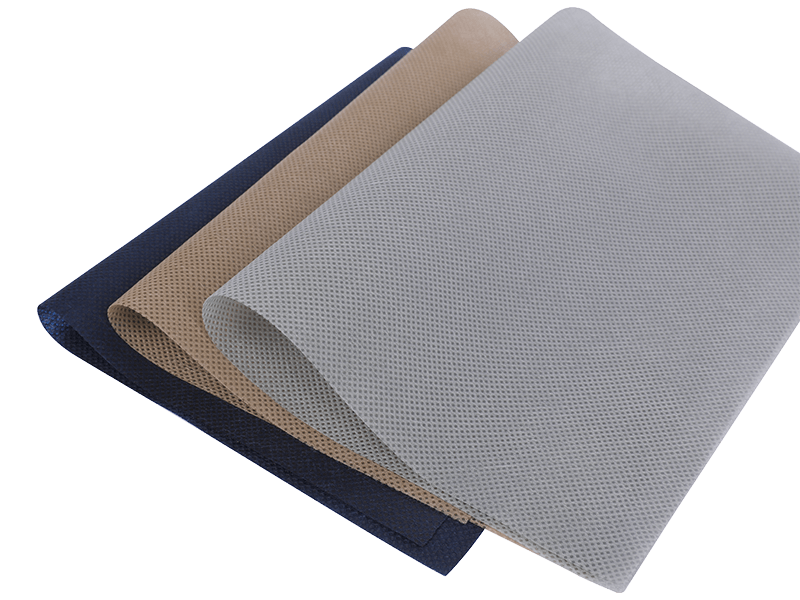

Spunbond Nonwoven Fabric is created through the spunbond process, which involves spinning continuous filaments of polymer fibers (commonly polypropylene) directly onto a conveyor belt, where they are bonded together using heat or pressure. This results in a lightweight, strong, and durable fabric that is widely used in applications requiring strength and cost efficiency.

Key Characteristics of Spunbond Nonwoven Fabric:

- Durability: Spunbond fabric is strong due to its continuous filament structure, which makes it resistant to tearing.

- Breathability: The fabric allows air to pass through, making it suitable for applications like medical gowns or agricultural covers.

- Lightweight: Typically ranging from 15 to 150 GSM (grams per square meter), spunbond fabrics are light but maintain structural integrity.

- Cost-Effective: The production process is relatively simple and economical, making spunbond fabrics suitable for mass production.

- Surface Texture: The surface of spunbond fabric is smooth and uniform, which can be easily printed or laminated if needed.

Common Applications of Spunbond Nonwoven Fabric:

- Medical masks, gowns, and caps

- Agricultural crop covers

- Geotextiles and construction fabrics

- Packaging materials

- Disposable hygiene products such as diapers and wipes

What is SMS Nonwoven Fabric?

SMS Nonwoven Fabric is a composite fabric made from three layers: Spunbond – Meltblown – Spunbond, which is why it is commonly referred to as “SMS.” The outer spunbond layers provide strength and durability, while the inner meltblown layer acts as a fine filter, providing high barrier properties against liquids and particles.

Key Characteristics of SMS Nonwoven Fabric:

- High Barrier Protection: The meltblown layer is extremely effective at filtering particles, bacteria, and viruses, making SMS fabrics suitable for medical and hygiene applications.

- Durability and Strength: The outer spunbond layers give the fabric mechanical strength and resistance to tearing.

- Breathability: Despite its multiple layers, SMS fabric remains breathable, allowing air circulation while maintaining barrier properties.

- Liquid Resistance: SMS fabrics can repel fluids, offering protection in medical and industrial environments.

- Comfortable Texture: The combination of layers provides a balance between softness and structure, enhancing comfort for wearable applications.

Common Applications of SMS Nonwoven Fabric:

- Surgical gowns, drapes, and masks

- Disposable protective clothing in laboratories and industrial settings

- Sanitary products, such as diapers and feminine hygiene items

- Filtration materials

- Medical packaging materials

Differences Between SMS Nonwoven Fabric and Spunbond Nonwoven Fabric

While both fabrics originate from polymer-based nonwoven technology, several key differences distinguish them.

1. Structure and Composition

- Spunbond Nonwoven Fabric: Made from continuous filaments of polymer fibers in a single layer, bonded thermally or mechanically.

- SMS Nonwoven Fabric: A multilayer composite consisting of two outer spunbond layers and an inner meltblown layer, combining strength and barrier performance.

2. Barrier Properties

- Spunbond Fabric: Offers limited barrier protection against fluids and micro-particles. Suitable for applications where breathability and durability are more important than protection from pathogens.

- SMS Fabric: Offers superior barrier properties due to the meltblown layer. Highly effective at blocking bacteria, viruses, and liquid penetration.

3. Durability and Strength

- Spunbond Fabric: Strong and tear-resistant, but less robust than SMS for high-stress applications.

- SMS Fabric: The outer spunbond layers enhance durability while the inner layer ensures barrier protection, making it ideal for critical medical applications.

4. Breathability

- Both fabrics are breathable, but SMS may feel slightly thicker due to its layered construction. However, it still allows air circulation while maintaining protective qualities.

5. Applications

- Spunbond Fabric: Ideal for lightweight, everyday applications like agricultural covers, packaging, and certain hygiene products.

- SMS Fabric: Preferred in healthcare, sanitation, and high-protection environments where liquid and particle barriers are essential.

6. Cost and Production

- Spunbond Fabric: Simpler to produce and generally less expensive.

- SMS Fabric: Requires additional production steps due to the meltblown layer, making it slightly more costly, but this cost is justified by its enhanced performance.

Choosing Between SMS and Spunbond Nonwoven Fabric

When selecting between SMS and spunbond nonwoven fabric, several factors should be considered:

- Intended Application: If high barrier protection is required, SMS is usually the better choice. For general use and lightweight applications, spunbond may be sufficient.

- Cost Considerations: Spunbond fabrics are more economical, making them suitable for large-scale, disposable applications.

- Comfort and Wearability: For products that contact the skin, SMS fabrics offer a good balance of softness and protection.

- Environmental Conditions: For outdoor or industrial applications, spunbond fabrics’ durability and tear resistance may be advantageous.

Conclusion

While Spunbond Nonwoven Fabric and SMS Nonwoven Fabric share some similarities in composition and production techniques, they serve distinct purposes. Spunbond is strong, lightweight, and cost-effective, making it suitable for everyday and industrial applications. SMS, on the other hand, combines the strength of spunbond layers with the high barrier properties of meltblown fabric, offering protection against fluids and pathogens, which is particularly important in medical and hygiene contexts.

By understanding these differences, manufacturers, designers, and consumers can make informed decisions when choosing the appropriate nonwoven fabric for their specific needs. Both materials contribute significantly to the versatility and innovation of nonwoven textiles, ensuring that the right balance between performance, comfort, and cost is achieved in every application.