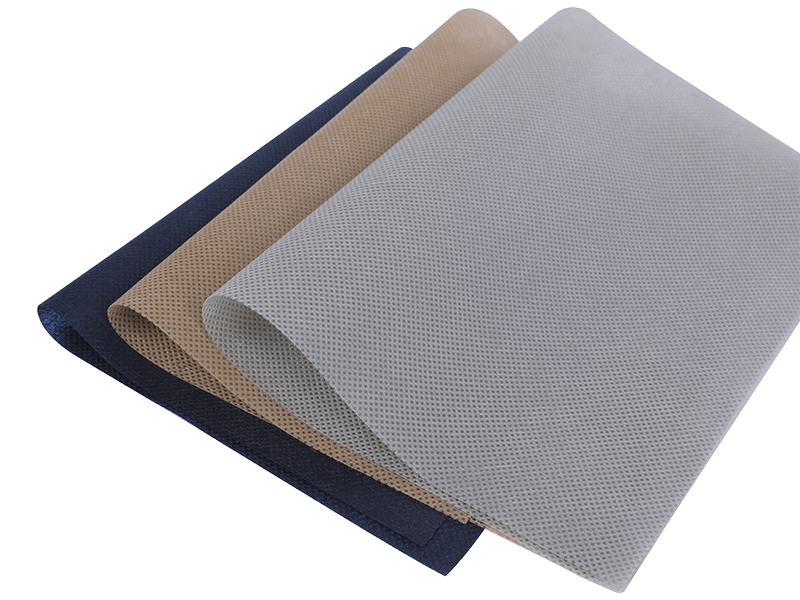

Nonwoven fabric is a versatile material used across various industries due to its cost-effectiveness, durability, and adaptability. Unlike traditional woven or knitted fabrics, nonwoven fabrics are made by bonding fibers together using mechanical, thermal, or chemical processes. This article explores the types of nonwoven fabric, their manufacturing processes, common applications, and advantages over traditional textiles.

Nonwoven fabrics are produced through several methods, depending on the desired properties. The key steps include:

Nonwoven fabrics are categorized based on their manufacturing process and end-use. Below is a comparison of the most common types:

| Type | Manufacturing Process | Key Properties | Common Uses |

| Spunbond Nonwoven | Extruded filaments laid into a web and thermally bonded | Lightweight, breathable, strong | Medical masks, disposable gowns, agriculture covers |

| Meltblown Nonwoven | Molten polymer blown into fine fibers and collected on a conveyor | Fine filtration, soft texture | PPE, air filters, oil absorbents |

| Needle-Punched Nonwoven | Fibers mechanically entangled with barbed needles | Dense, durable, high strength | Geotextiles, automotive carpets, insulation |

| Thermal Bonded Nonwoven | Heat applied to melt fibers at contact points | Soft, flexible, lightweight | Hygiene products, wipes, packaging |

| Wet-Laid Nonwoven | Fibers suspended in water, then drained and dried | Smooth surface, uniform texture | Tea bags, medical drapes, filters |

Nonwoven fabrics offer several benefits over traditional textiles:

Due to their adaptability, nonwoven fabrics are used in diverse industries:

| Industry | Applications |

| Medical & Hygiene | Surgical masks, diapers, wound dressings, disposable gowns |

| Agriculture | Weed control fabric, plant protection covers, seed blankets |

| Automotive | Headliners, trunk liners, insulation, air filters |

| Packaging | Shopping bags, protective wraps, food packaging |

| Construction | Roofing membranes, house wrap, geotextiles |

Understanding the distinctions helps in selecting the right material:

| Feature | Nonwoven Fabric | Woven Fabric |

| Production Speed | Faster, continuous process | Slower, requires yarn preparation |

| Strength | Directional (varies by bonding method) | Uniform in warp and weft directions |

| Breathability | Adjustable (depends on fiber density) | Generally more breathable |

| Cost | Lower (less labor-intensive) | Higher (weaving process) |

While some nonwovens are disposable, sustainable options are gaining traction:

Innovations are driving the industry forward:

Nonwoven fabrics are indispensable in modern industries due to their versatility, cost-efficiency, and functional properties. From medical applications to agricultural uses, their adaptability ensures continued growth. As sustainability becomes a priority, advancements in eco-friendly nonwovens will further expand their applications.