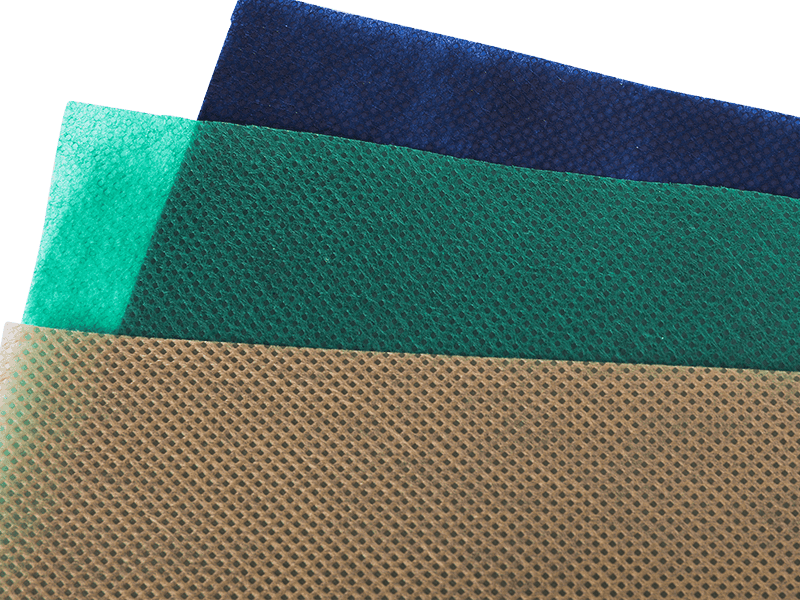

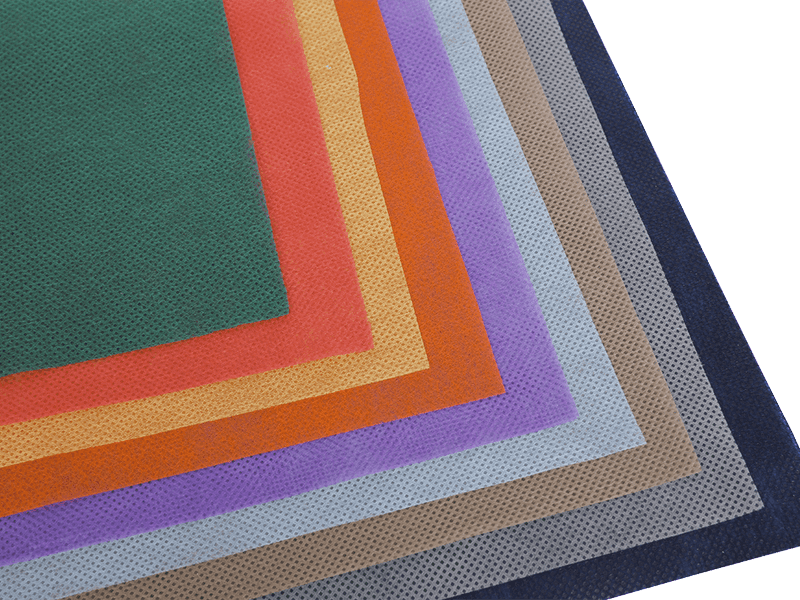

As sustainability regulations tighten across Europe and North America, the demand for flushable nonwoven materials is on the rise. Buyers in the baby care, household, medical, and industrial sectors are now seeking products that balance softness, strength, and reliable dispersibility in wastewater systems. With certified INDA/EDANA GD4 flushability testing and the ability to customize basis weight (gsm) and wood pulp ratio, manufacturers can provide tailored solutions that meet both performance needs and market compliance.

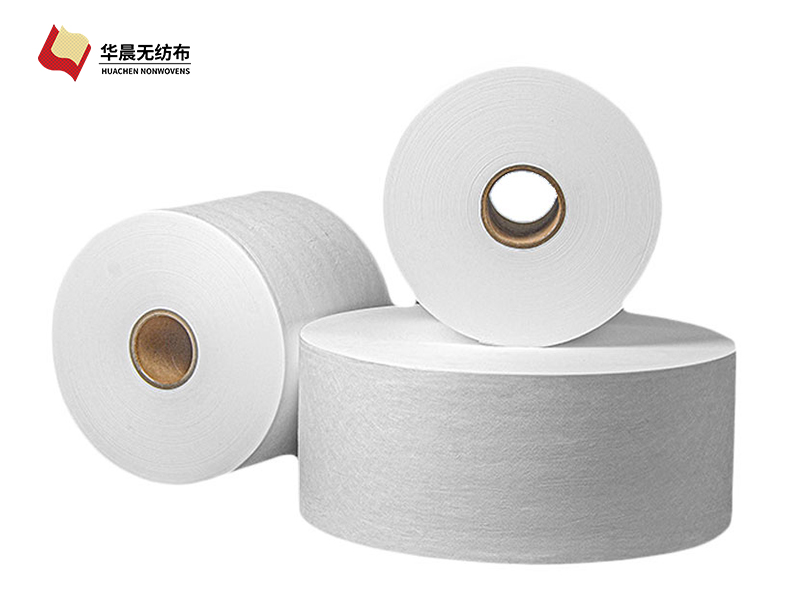

1. Production Process: How Flushable Nonwovens Are Made

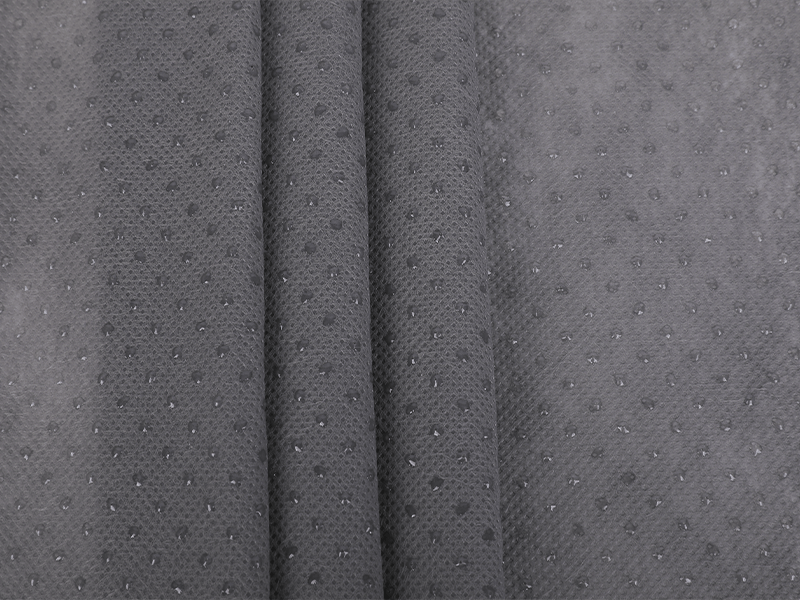

Most flushable substrates are produced using spunlace (hydroentanglement) or wet-laid processes, where a blend of wood pulp and short fibers is bonded with high-pressure water jets. By avoiding chemical binders and adjusting fiber composition, suppliers can achieve:

-

High water dispersibility – critical for passing GD4 tests.

-

Soft texture – ideal for sensitive skin applications.

-

Adequate wet strength – ensuring products do not fall apart during use.

The choice of fiber length, pulp percentage, and gsm directly influences softness, durability, and dispersibility.

2. Why GD4 Certification Matters

The GD4 flushability test protocol developed by INDA and EDANA is currently the recognized industry standard. It evaluates:

-

Disintegration in water over time

-

Compatibility with sewage and wastewater treatment systems

-

Biodegradability under aerobic and anaerobic conditions

For B2B buyers, choosing a supplier with GD4-certified products ensures reduced compliance risk and better acceptance in regulated markets.

3. Application Scenarios

Flushable nonwoven materials are widely applied across consumer and professional markets:

-

Baby wipes & facial wipes: Lightweight (28–35 gsm) with high pulp ratio (80–90%) for softness and fast disintegration.

-

Household cleaning wipes: Medium weight (40–55 gsm) with balanced pulp/fiber composition for strength and easy flushing.

-

Medical & disinfectant wipes: Higher gsm (55–70) with reinforced structure to withstand alcohol-based formulas while maintaining flushability.

-

Industrial-grade wipes: Heavy-duty (70–85 gsm) with higher fiber content for durability, yet still designed to pass GD4 dispersibility standards.

4. Key Advantages for Buyers

-

Customizable Specifications – Adjust gsm, wood pulp percentage, and fiber type to match end-use requirements.

-

Certified Flushability – Products verified through GD4 testing minimize the risk of pipeline blockages and regulatory issues.

-

Regulatory Compliance – Meeting EU and U.S. expectations on sustainability and wastewater compatibility.

-

Market Flexibility – From light baby care products to heavy-duty industrial wipes, options are available for multiple sectors.

5. Practical Advice for B2B Procurement

-

Request Third-Party Test Reports: Always confirm GD4 compliance with independent laboratory results.

-

Match GSM to Application: Lighter gsm for softness and faster dispersibility; heavier gsm for strength in cleaning or industrial use.

-

Consider Storage Conditions: Long-term wet storage can affect dispersibility; ask for performance data after simulated shelf life.

-

Plan for Future Regulations: Choose suppliers capable of adjusting pulp ratios and compositions as sustainability requirements evolve.

Conclusion

Flushable nonwoven fabrics are more than just an eco-friendly claim—they represent a technical balance of strength, softness, and dispersibility. With certified INDA/EDANA GD4 testing and full customization of gsm and pulp ratios, suppliers can help European and U.S. buyers achieve both regulatory compliance and market success. For importers and distributors, partnering with manufacturers that provide flexible specifications and verifiable testing is the key to staying ahead in this fast-growing sector.

English

English 中文简体

中文简体 русский

русский